Our Activities

Panasonic R&D Center Singapore’s Solution to Robotics-Integrated Smart Inspection of Built Environments (RISE)

February 10, 2022 |

The COVID impact has not only changed how the construction industry does business, but also caused increased reliance on construction technology – specifically, the innovations that can enhance efficiency. Traditionally, the construction industry heavily depends on manual inspection at different stages of a construction project to ensure quality, safety and comfort of a finished building. However, labour shortage is a common problem confronting the construction industry in many developed countries due to the aging population and declining workforce. At that, Panasonic R&D Center Singapore is working on a Robotics-Integrated Smart Inspection of Built Environments (RISE) project to improve productivity for building quality inspection and evaluation, with an aim to alleviate the labour shortage problem and meet the quality demand for infrastructure and real-estate projects in Singapore and around the world.

The RISE project is aimed to provide a ‘Robotics Solution’ to ‘Accurate Construction Quality and Progress Monitoring’, and ‘Effective Workplace Safety inspections’ with a ‘Data Management System’, by advancing and integrating Panasonic R&D Center Singapore’s core technologies in robotics, AI computer vision, 3D and software development. As the construction industry is one of the least automated industries due to ragged and unstructured work environments on construction sites, the outcome of the RISE project is perceived to contribute to the gap-fill between the robotics and construction industries.

Supported by BCA

The RISE project is funded by the Building and Construction Authority (BCA) and the National Robotics Program (NRP) of the Singapore government. To deliver high-quality buildings to owners, building quality assessment is always on the radar of BCA, which, in turn, makes standards such as TOP (Temporary Occupation Permit) inspection and CONQUAS (Construction Quality Assessment System) for finished buildings. To improve productivity of Singapore’s construction industry, BCA is also pushing for digitalization of construction project documentation, management and approval, as well as investing to advance data centralization and process automation technologies in collaboration with research institutions. By working with BCA and other collaborators in the construction industry, Panasonic R&D Center Singapore is developing technologies to solve the pain points in the construction industry and provide solutions in line with market demand.

Main features

The main features of the RISE solution include:

- The inspection robot platform leveraging Panasonic’s technologies used in HOSPI, the Panasonicautonomous delivery robots, is designed for high automation and safety in operation, and equipped with perception sensors and a 3D scanner, to provide functionalities of mapping, localization, self-navigation, obstacle avoidance, remote control, scanning scheduling and data collection. The scanner unit is detachable to enable data collection in the construction environment inaccessible to robots.

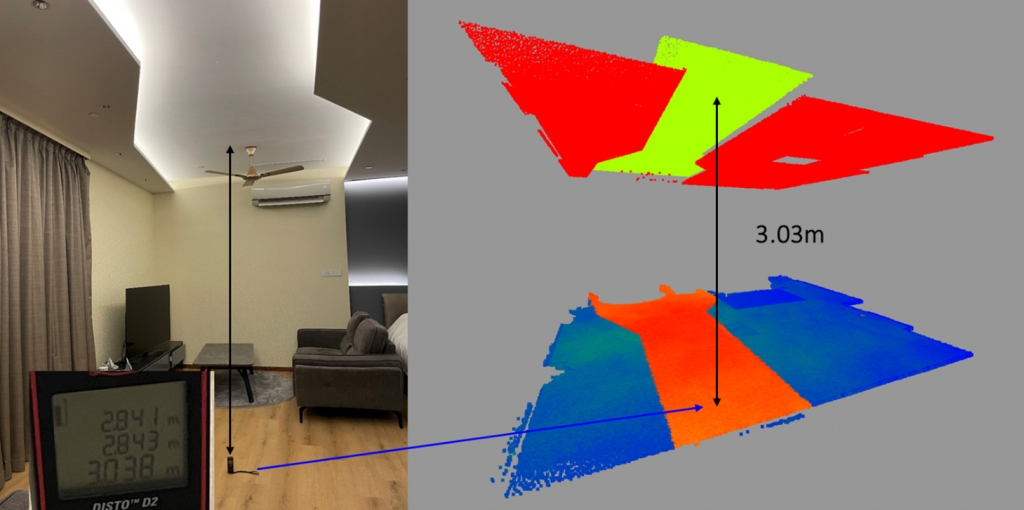

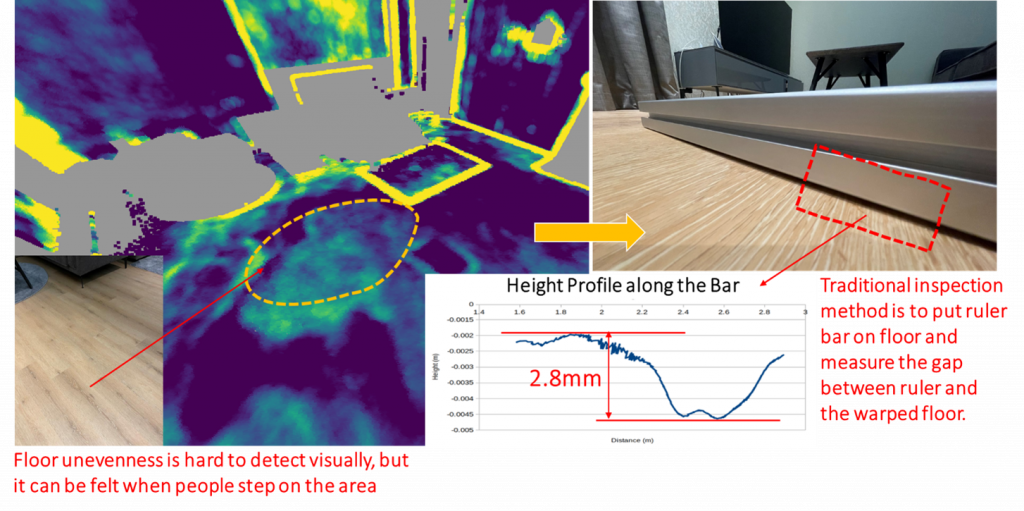

- The AI and 3D analytic engines are designed for precise analysis of building quality, with the functionalities of room structure analysis and modelling, geometry measurement, intolerance and defect detection and positioning in a building. With the 3D-visual data from a few scans or even a single scan, analysis of multiple inspection items can be conducted simultaneously to improve efficiency. At different construction stages from foundation to finishing, various inspections need be conducted by engineers and technicians to make sure of the construction being compliant with the corresponding standards, codes and regulations. Our RISE project is aimed for the inspection items at the finishing stage to fulfil the requirements for TOP and CONQUAS, with accuracy up to 3mm. The technologies Panasonic R&D Center Singapore deployed for this project can also be extended to inspection requirements at different construction stages.

- By deploying Panasonic R&D Center Singapore’s AI technologies for human detection, vehicle/heavy machinery detection, mask detection, safe distancing, and PPE (personal protective equipment) detection, the real-time safety inspection is made possible on a construction site. Due to the nature of a construction project, work-related or workplace accidents are common. However, there are always safety lapses at a worksite where workers might fail to abide by safety rules. With Panasonic R&D Center Singapore’s real-time lightweight AI technology deployed on a robot platform, safety incompliance is immediately detectable at a worksite, thus alerting the workers to an imminent accident risk.

- The centralized construction data management system is installed to store all the inspection data in alignment with geo-positions. This feature enables a user to trace the construction progress and change of the building. The user can also track whether the intolerance or defect inspected in a previous scan has been rectified by verifying it in the new scan. Our mapping and positioning technologies enable the geo-alignment of the data from different scanning times. On top of that, Panasonic R&D Center Singapore’s world-leading 3D data compression technology is deployed for efficient data storage and visualization.

(The built-up inspection robot platform)

(The scanner on top of the robot platform collects high-resolution and high-accuracy 3D and visual data to facilitate precise analysis of building quality)

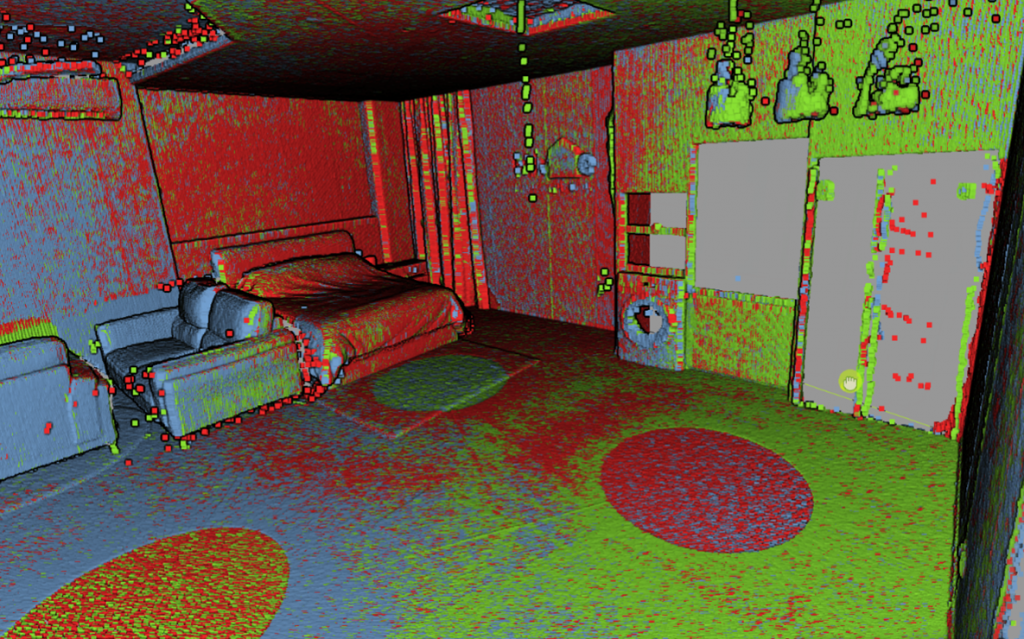

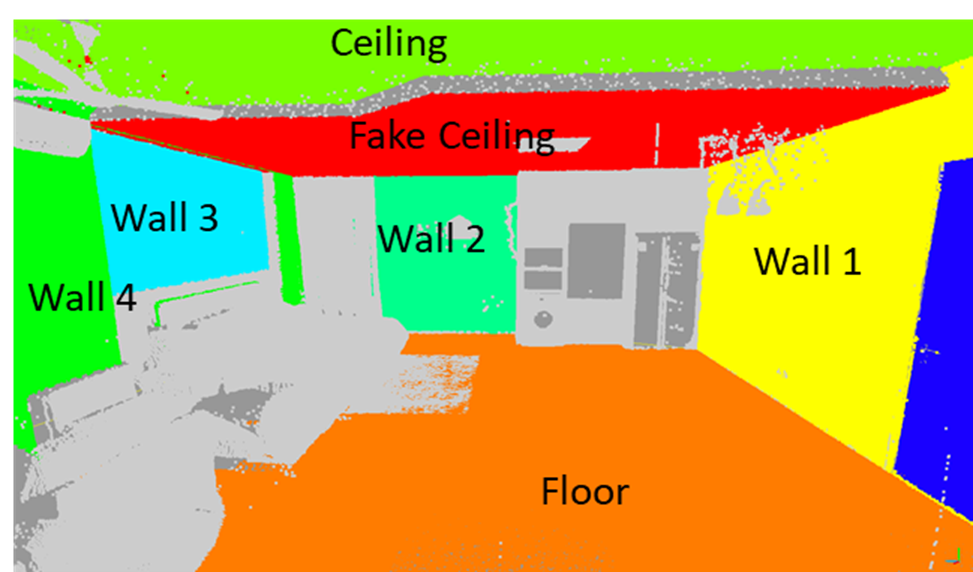

(Room modelling and structure analysis from the collected 3D-visual data by using AI and 3D analytic engines)

(Floor level and height clearance measurement required by TOP inspection, with allowable error limits less than 1cm compared with laser measurement)

(Floor unevenness checking required by CONQUAS, in which the 3mm unevenness along 1.2m is considered to be intolerance. On the left of the image, the unevenness is highlighted in yellow, while the blue portion indicates the smooth surface. Our technology is able to provide a floor surface height profile to detect the 3mm unevenness)

Related Posts

HomeX For ASEAN

Life Gets A (Much Needed) Update with HomeX, Panasonic’s integrated lifestyle platform. Panasonic leverages on its global reputation for providing…

Read more

Bosco App: Cyber-well-being for your child using AI

Utilizing our deep learning based technologies for multimodal processing of image, text and video contents, we provide machine intelligence backend…

Read more

Online Presentation: No longer static and stale

In these challenging and uncertain times, many activities cannot help but be conducted online. Traditionally, due to the fact that…

Read more

People Before Products

The exponential pace of progress in Artificial Intelligence has led to an increasingly worrying narrative on the ethics and regulatory…

Read more